SandX 40″ x 86 5/8″ Deluxe Two Head Wide Belt Sander

CWI-S4086-S2-M2

$ 31,999.95 CDN

+ $149 flat rate shipping on most items/ locations.

This heavy duty SandX 40″ x 86 5/8″ double sanding head wide belt sander is truly a unique machine with size and performance a step up on any competitor in its class. A true step above for any woodworking shop looking for a good quality wide belt sander with extra width and better performance. SandX Abrasive machines are built to very high standards for woodworkers needing exceptional performance but still at reasonable value.

Product Details

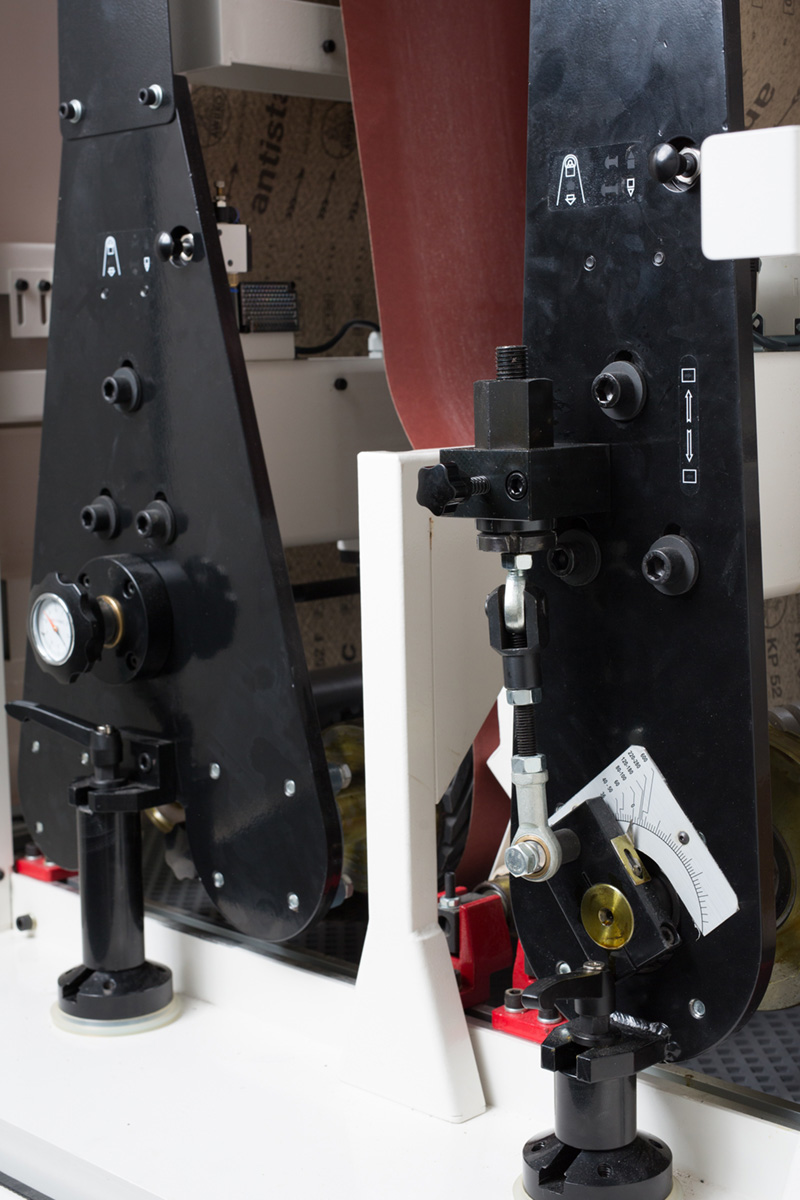

The CWI-S4086-S2 available in three phase power only features separate motors for each sanding head. The first contact head has a 20 HP sanding motor for heavier stock removal while the second finishing head with 2” platen uses a 15 HP sanding motor.

The use of two separate heads will increase production times by being able to sand with two different grits of abrasive at the same time. The first contact head can also be lifted to not have contact with the work piece for fine finishing applications or as well can be adjusted to ensure correct calibration of the two sanding head heights.

The use of two separate heads will increase production times by being able to sand with two different grits of abrasive at the same time. The first contact head can also be lifted to not have contact with the work piece for fine finishing applications or as well can be adjusted to ensure correct calibration of the two sanding head heights.

Of special note on this machine is the almost 40” sanding working width capacity as well as the extra-long 86 5/8” sanding belt length. Most wide belt sanders in this category use 60”-75” sanding belt lengths. The SandX CWI-S4086 sander uses an 86 5/8” belt length like other European made heavy duty sanders. The extra length accomplishes two things. First the extra length means the belts will run cooler as they have more time for the belt surface to rotate. Second the frame and structure of the machine are built much heavier to support the lager belt meaning a far better built machine.

Tracking trueness of the abrasive sanding belt is done electronically for constant “maintenance free” usage of the belt tracking mechanism.

Many competitive machines use pneumatic abrasive belt tracking components which require constant maintenance of diaphragms, pumps and air lines which deteriorate over a period of time.

The SandX wide belt sander uses an electronic eye system with micro switches to activate the oscillation of the sanding head to keep the sanding belts tracking properly on the machine.

Many competitive machines use pneumatic abrasive belt tracking components which require constant maintenance of diaphragms, pumps and air lines which deteriorate over a period of time.

The SandX wide belt sander uses an electronic eye system with micro switches to activate the oscillation of the sanding head to keep the sanding belts tracking properly on the machine.

One of the exclusive features on the SandX wide belt sander is the abrasive belt cleaning devise on the sanding head.

This air jet cleaning feature ensures better sanding belt life whether you are using cloth or paper belts by blowing dust free from the belts abrasive surface while at the same time keeping the belt at a cool temperature to ensure less break down of the sanding material.

This air jet cleaning feature ensures better sanding belt life whether you are using cloth or paper belts by blowing dust free from the belts abrasive surface while at the same time keeping the belt at a cool temperature to ensure less break down of the sanding material.

Also a very important feature is the electronic work piece measuring device.

Simply set your work piece on the measurement platform and the machine will automatically raise to the height for the appropriate level for sanding that work piece.

No need for calipers or tape measures. The table rise/fall motor is a 1/2 HP motor which can also be operated manually with push buttons to set the desired height with a digital controller and height read out.

Measurements can be set in either metric or imperial measurement

Simply set your work piece on the measurement platform and the machine will automatically raise to the height for the appropriate level for sanding that work piece.

No need for calipers or tape measures. The table rise/fall motor is a 1/2 HP motor which can also be operated manually with push buttons to set the desired height with a digital controller and height read out.

Measurements can be set in either metric or imperial measurement

SandX wide belt sanders also offer electronic limit switches, safety shut down bar and fast acting disc brakes.

The machine will automatically stop if you experience a sanding belt breakage.

The machine will automatically stop if you experience a sanding belt breakage.

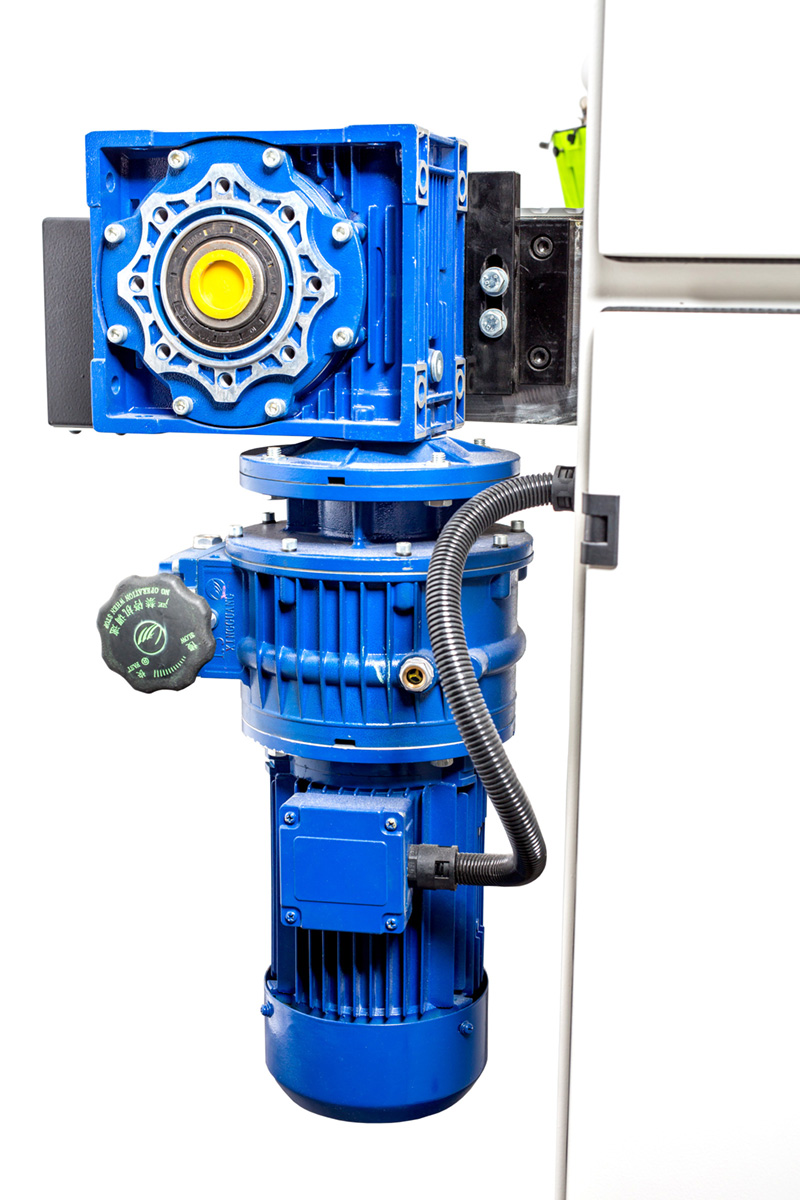

The variable speed rubber conveyer belt travels at 16-81 feet per minute by a very strong 2 HP feed motor and is controlled by an easy adjust automatic tracking device.

The conveyer table is supported by very heavy duty jack screws for years of trouble free table adjustment and trueness.

The conveyer table is supported by very heavy duty jack screws for years of trouble free table adjustment and trueness.

SandX wide belt sanders are built with an abundance of quality features to ensure years of exceeding performance at a very affordable price.

Specifications:

– M2- Contact Head 20 HP – Finishing Head 15HP 220/3/60 Electrics

– Contact Head 190mm Dia Steel Drum

– Combination Finishing head with 160mm Dia Rubber Drum at 70 Durometer with 2″ platen

– 1/2 HP Power Rise and Fall Table

– Automatic Tracking of Conveyer Belt

– 2 HP Conveyer Belt Feed Motor with Variable Speeds of 16′ – 81′ / minute

– Photoelectric Sanding Belt Tracking and Oscillation

– Wrenchless Adjustment of Sanding Belt Tracking

– Automatic Disc Brakes in case of belt breakage

– Safety Emergency Push Stop Bar at front of machine

– Centralized Control Panel with Amp Meter

– Electronic Automatic Digital Height Controller (metric or imperial)

– Electronic Digital Work Piece Thickness Measurement

– Air Jet Belt Cleaning and Cooling

– Four Pressure Rollers to ensure proper work support

– Sanding Belt Size 40″ x 86 5/8″

– Sanding Working Width 39.5”

– Maximum Working Height of 6.25″

– Four 5” Dust outlets

– Required Air Pressure .6MPa

– Required Dust Collection 3600CFM

– Machine Weight of 5050 LBS

– Dimensions 70” x 85” x 82”

– CSA Certified

– M2- Contact Head 20 HP – Finishing Head 15HP 220/3/60 Electrics

– Contact Head 190mm Dia Steel Drum

– Combination Finishing head with 160mm Dia Rubber Drum at 70 Durometer with 2″ platen

– 1/2 HP Power Rise and Fall Table

– Automatic Tracking of Conveyer Belt

– 2 HP Conveyer Belt Feed Motor with Variable Speeds of 16′ – 81′ / minute

– Photoelectric Sanding Belt Tracking and Oscillation

– Wrenchless Adjustment of Sanding Belt Tracking

– Automatic Disc Brakes in case of belt breakage

– Safety Emergency Push Stop Bar at front of machine

– Centralized Control Panel with Amp Meter

– Electronic Automatic Digital Height Controller (metric or imperial)

– Electronic Digital Work Piece Thickness Measurement

– Air Jet Belt Cleaning and Cooling

– Four Pressure Rollers to ensure proper work support

– Sanding Belt Size 40″ x 86 5/8″

– Sanding Working Width 39.5”

– Maximum Working Height of 6.25″

– Four 5” Dust outlets

– Required Air Pressure .6MPa

– Required Dust Collection 3600CFM

– Machine Weight of 5050 LBS

– Dimensions 70” x 85” x 82”

– CSA Certified

Confirm Availability & Shipping for the SandX CWI-S4086-S2-M2