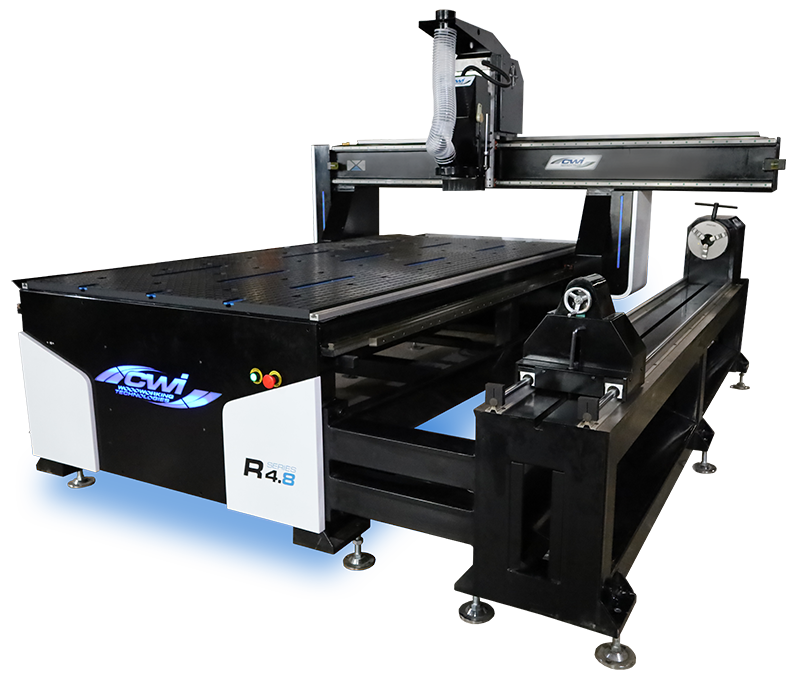

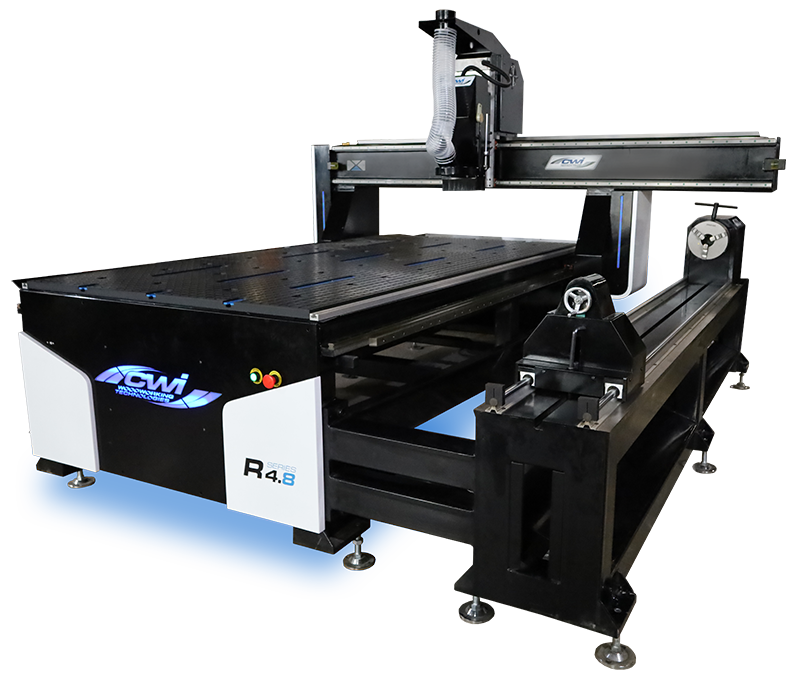

Basic R4.8 CNC Router

4′ x 8′ w. Rotary Attachment

CWI-CNC4896B-4XS

$ 27,999.95 CDN

+ $149 flat rate shipping on most items/ locations.

The Basic “R” Series of machines are truly a unique professional CNC option for not only working in standard 3-axis machining, but also with fourth axis machining for working in the round. The “R” Series machines are perfect for furniture builders, prototyping, stage and movie set production and wood lathe operations.

Product Details

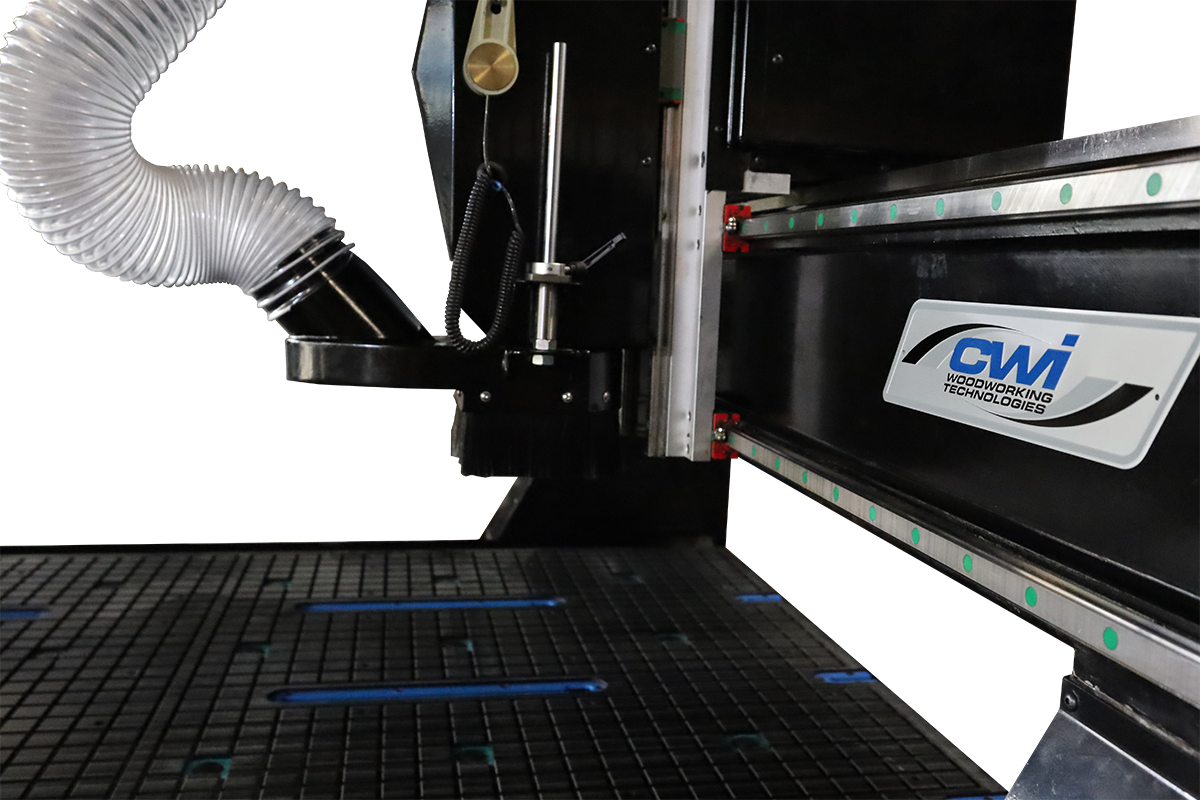

The R4.8 utilizes a T-slot Bakelite vacuum table making it “vacuum ready” for hold down work of sheet goods.

The performance and features of the R4.8 include a Side-Mounted Rotary Fourth Axis Station with a 16” diameter x 84” length capacity, under-the-frame electrical controls cabinet, as well as automatic tool change options.

All Basic series of CNC routers start with a heavy duty welded steel floor model frame. Under the frame are six heavy-duty 5″ diameter adjustable feet for solid footing on the shop floor but the machines also come with heavy duty castors for those looking for more mobility of the machine.

The performance and features of the R4.8 include a Side-Mounted Rotary Fourth Axis Station with a 16” diameter x 84” length capacity, under-the-frame electrical controls cabinet, as well as automatic tool change options.

All Basic series of CNC routers start with a heavy duty welded steel floor model frame. Under the frame are six heavy-duty 5″ diameter adjustable feet for solid footing on the shop floor but the machines also come with heavy duty castors for those looking for more mobility of the machine.

The heavy duty steel gantry is powered by High torque Nema 34 extra strong stepper motors. Standard is two steppers on “Y” axis, one on “X” axis and one on “Z” axis. The gantry rides on accurate THK linear guide ways and travel by ultra precise rack and pinion movements in X, Y movements. The Z axis is driven by 20mm ultra precise ball screw. To make set up simple we include a moveable tool measure devise for making accurate measurements of tool height when starting your projects.

On the Basic R4.8 we use the industry leading commercial quality HSD 3kw (4 HP) router spindle, which comes with 1/8″, 1/4″, 3/8″ and 1/2″ high precision ER25 collets. HSD is the leading Italian manufacturer of CNC spindles throughout the world. Users will find the speed, power and precision of the HSD spindle second to none. The 3-phase spindle is converted by a Delta phase inverter to run at 0-18,000 rpm on single-phase 220-volt power.

For educational users we now offer Protex Safety Cages in various sizes as options for safety in the work shop. The 6′ tall wire mesh cages typically have a 48″ swing door with electrical interlock so the machine will stop running its program if the door is opened. The cages can have one, two, three or four walls in many sizes.

The machining area is 49.5″ x 98.5″ with a gantry clearance height of 12″. This speedy powerful machine can travel at 985″/minute and weighs in at 3,740 lbs and takes up 80″ x 126″ x 65″ of floor space.

The simple operation of the machine is functioned with an NC Studio model NK105 G3 hand held controller. Simply download your work program from your computer to a memory stick, slide it into the USB port on the control panel and the hand held controller works everything from there – perfect for ease of operation and keeping your computer out of the dusty world of your workshop.

The simple operation of the machine is functioned with an NC Studio model NK105 G3 hand held controller. Simply download your work program from your computer to a memory stick, slide it into the USB port on the control panel and the hand held controller works everything from there – perfect for ease of operation and keeping your computer out of the dusty world of your workshop.

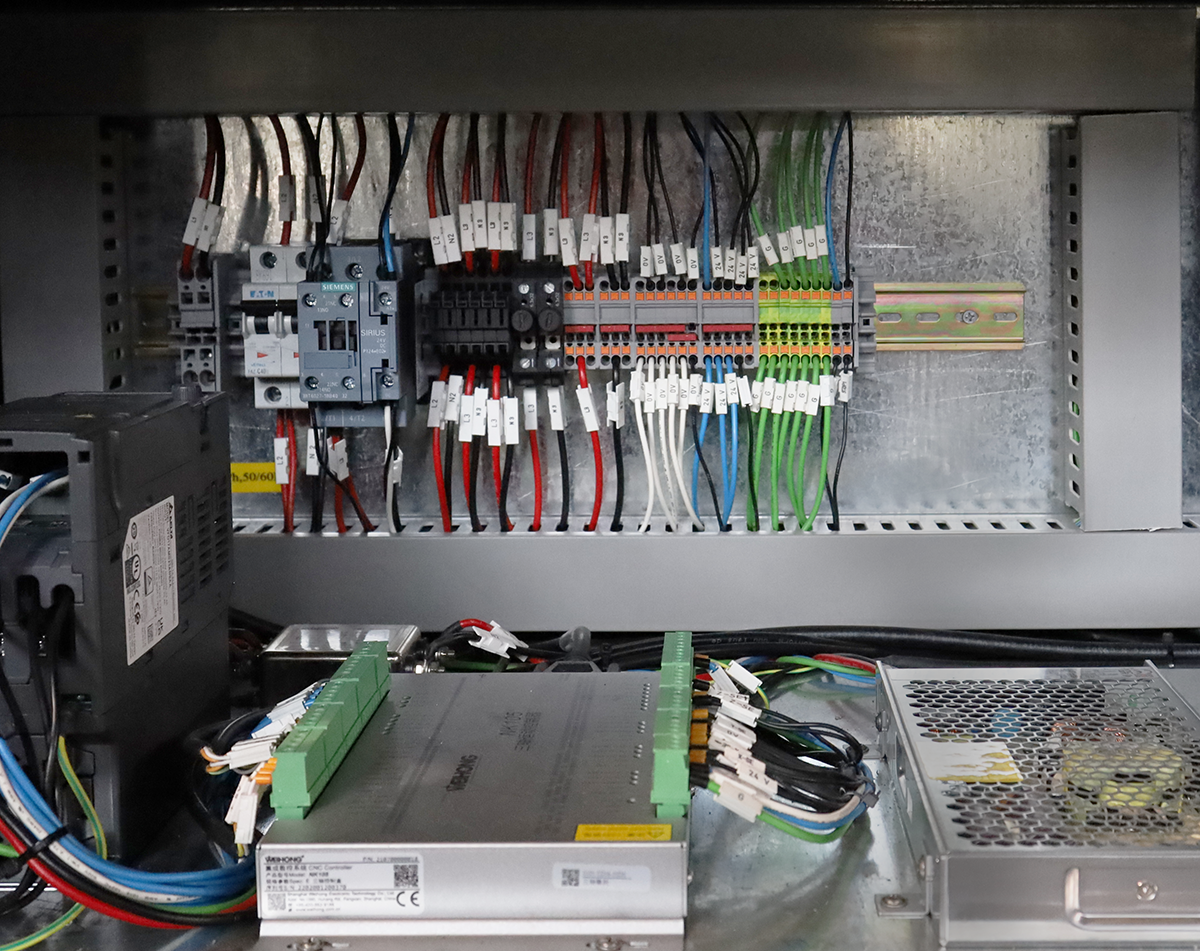

The “guts” of the Basic R4.8 is an elaborate control box mounted under the table of the machine to save on floor space. It’s full of Siemens CSA contactors, fuses and holders, Delta Inverter, motor controls and NC Studio control boxes. We use Omron micro limit switches for controlling stops and movements of the home positioning.

The Basic R4.8 is fully CSA certified for use in Canadian and American schools and commercial applications.

The Basic R4.8 is fully CSA certified for use in Canadian and American schools and commercial applications.

The Basic R4.8 operates on 220-volt power on a standard 20-amp 220-volt circuit breaker. For dust collection we include a dust boot with a 4” dust port which is connected to an upper 4” inlet to keep the dust collection high above the operations on the machine. The hood itself easily adjusts up and down for various router bit sizes and has a swing away opening to make tool changes a breeze.

Design software is not included. CWI recommends the Vectric CNC products. We stock V-Carve Pro and Aspire. Other options for these machines you may want to consider are cutting tools and dust hose. The Basic series of CNC from CWI are available in many sizes and different features from 4×4, 4×8 and 5×10 working areas, vacuum tables and vacuum pumps, lubrication for cutting tools, fourth axis and even with automatic tool changers. Just browse our website for other standard models now available. We can also custom design for special needs.

The Basic R4.8 will offer better performance, world class components, quality, and features than any competitive machine in its class.

Specifications:

– Working area: 49.5″ x 98.5″ x 11.75″

– 4th Axis Rotary Attachment

– 3 KW (4 HP) HSD 18,000 RPM Italian industrial air-cooled spindle

– ER25 precision router bit collets

– 1/8″, 1/4″ and 1/2″ collets included

– T-slot Dual Layer Bakelite vacuum table

– Gantry height of 12″

– NC Studio NK105 G3 handheld controller

– USB information transfer port

– Hidden electronics cabinet in Frame of machine

– Siemens disconnect w/safety lockout

– Four High Torque NEMA 34 Stepper drive motors 4.28 amps

– Stepper drive motors torque of 50kg/cm

– DELTA inverter

– SHIMPO reducer

– Ultra Precise Rack and Pinion Movement in X & Y axis

– 20MM Ball Screw Movement of Z axis

– Traveling speed 985″/minute

– THK linear rail

– Tool measuring sensor

– German Siemens electronics

– Japanese Omron switches

– 4″ Dust Collection Inlet

– Floor Space 2027 x 1730 x 1656 mm 80″ x 68″ x 65″

– CSA Certified

– 1PH 220V 60HZ

– Weight 1,700 kg 3,740 lbs.

– Shipping Size 85″ x 126″ x 73″

– Shipping Weight 1,925 kg 4,240 lbs.

– Plywood crate

– Working area: 49.5″ x 98.5″ x 11.75″

– 4th Axis Rotary Attachment

– 3 KW (4 HP) HSD 18,000 RPM Italian industrial air-cooled spindle

– ER25 precision router bit collets

– 1/8″, 1/4″ and 1/2″ collets included

– T-slot Dual Layer Bakelite vacuum table

– Gantry height of 12″

– NC Studio NK105 G3 handheld controller

– USB information transfer port

– Hidden electronics cabinet in Frame of machine

– Siemens disconnect w/safety lockout

– Four High Torque NEMA 34 Stepper drive motors 4.28 amps

– Stepper drive motors torque of 50kg/cm

– DELTA inverter

– SHIMPO reducer

– Ultra Precise Rack and Pinion Movement in X & Y axis

– 20MM Ball Screw Movement of Z axis

– Traveling speed 985″/minute

– THK linear rail

– Tool measuring sensor

– German Siemens electronics

– Japanese Omron switches

– 4″ Dust Collection Inlet

– Floor Space 2027 x 1730 x 1656 mm 80″ x 68″ x 65″

– CSA Certified

– 1PH 220V 60HZ

– Weight 1,700 kg 3,740 lbs.

– Shipping Size 85″ x 126″ x 73″

– Shipping Weight 1,925 kg 4,240 lbs.

– Plywood crate

Options Available:

– 60″ x 120″ Working Area

– 8 HP HSD Brand Router Spindle

– 16” Gantry Height

– Automatic Tool Change

– Vectric V-Carve Pro software

– Vectric Aspire software

– Starter tooling kit

– Onsite Training

– Protex Security Cage with Electrical Interlock

– 60″ x 120″ Working Area

– 8 HP HSD Brand Router Spindle

– 16” Gantry Height

– Automatic Tool Change

– Vectric V-Carve Pro software

– Vectric Aspire software

– Starter tooling kit

– Onsite Training

– Protex Security Cage with Electrical Interlock

Confirm Availability & Shipping for the Basic CWI-CNC4896B-4XS