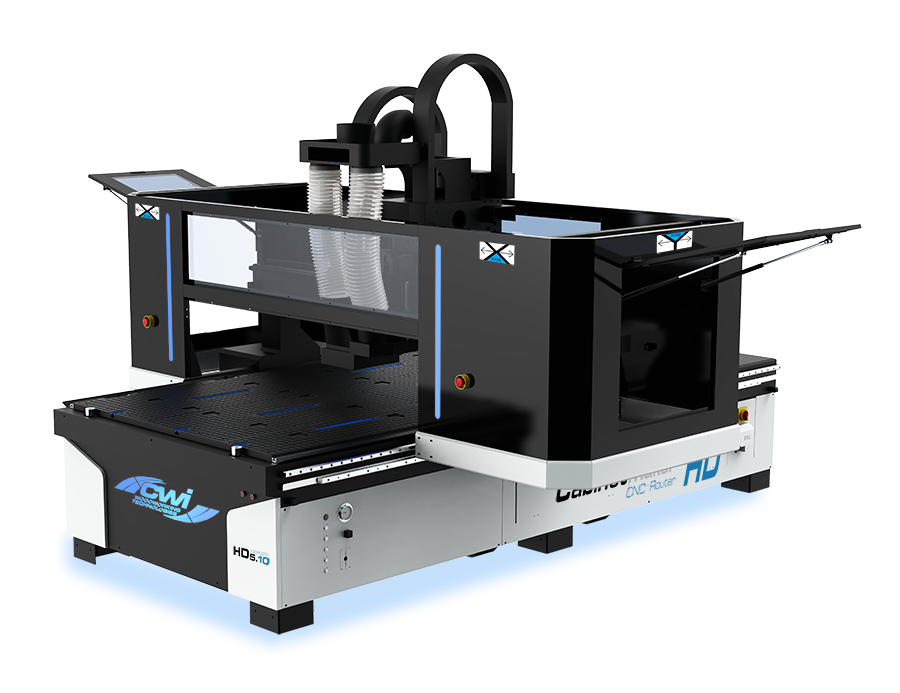

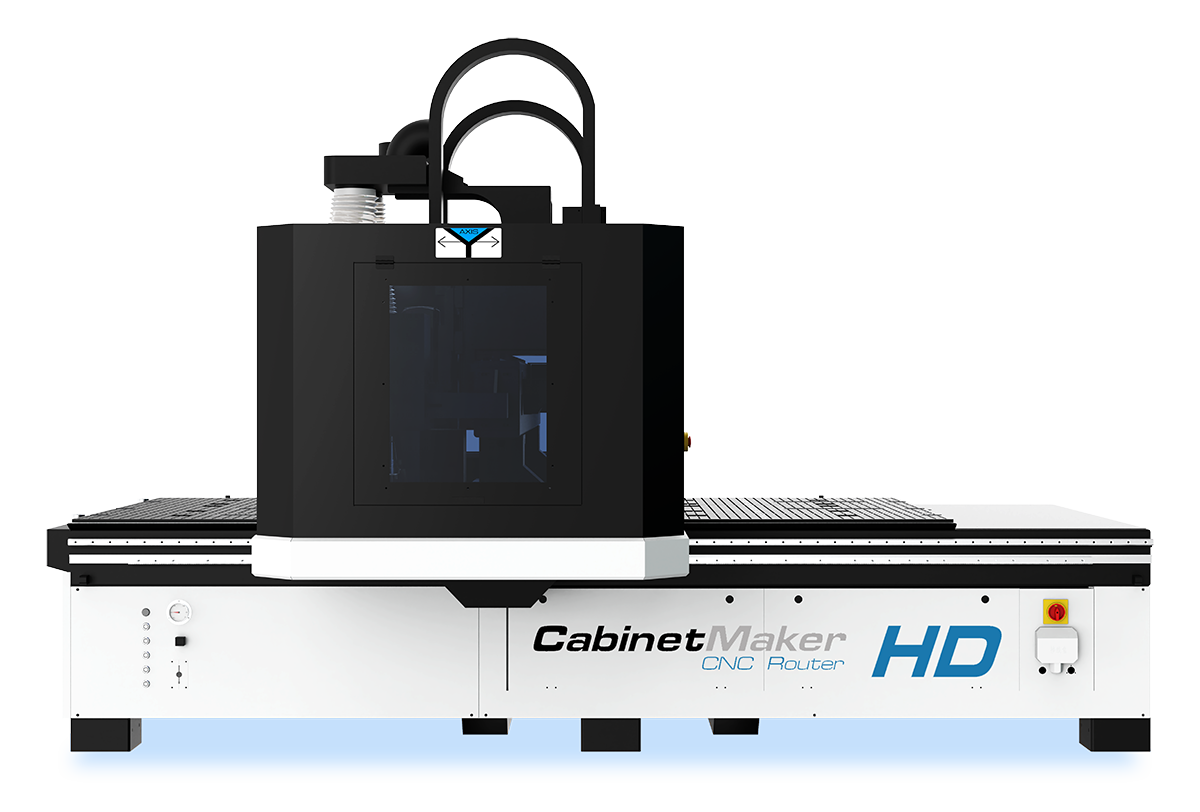

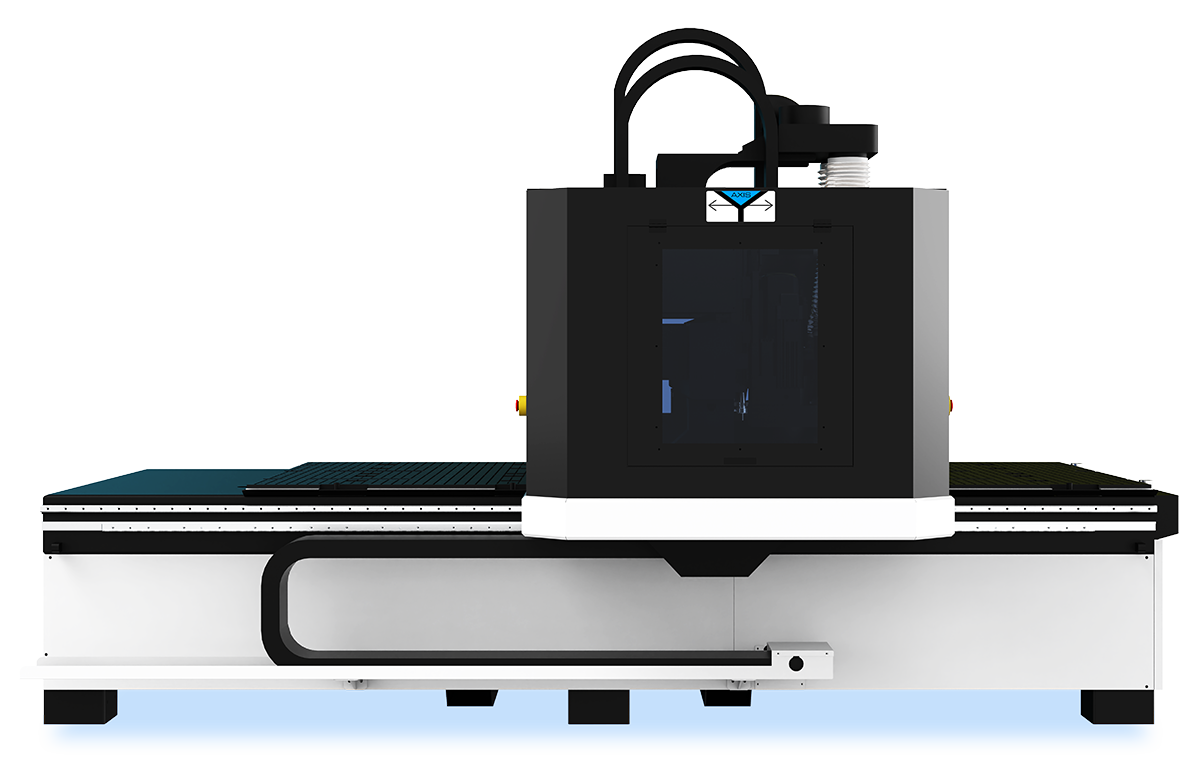

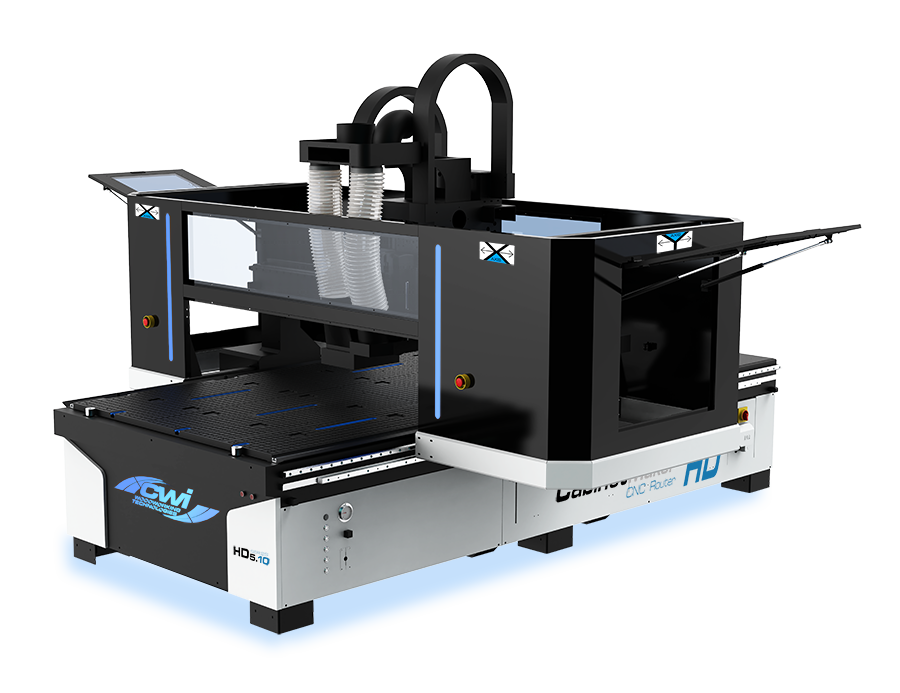

CabinetMaker HD CNC Router

5′ x 10”

CWI-CNC60120C-HD

$ 74,999.95 CDN

+ $149 flat rate shipping on most items/ locations.

The CabinetMaker HD was developed by CWI Woodworking Technologies for heavier production capabilities of today’s kitchen or closet manufacturer. This machine is standard in a 5’ x 10’ working area but can be special ordered in a 4’ x 8’ working area. CWI also offers similar models with automatic unloading or automatic loading/unloading versions.

Product Details

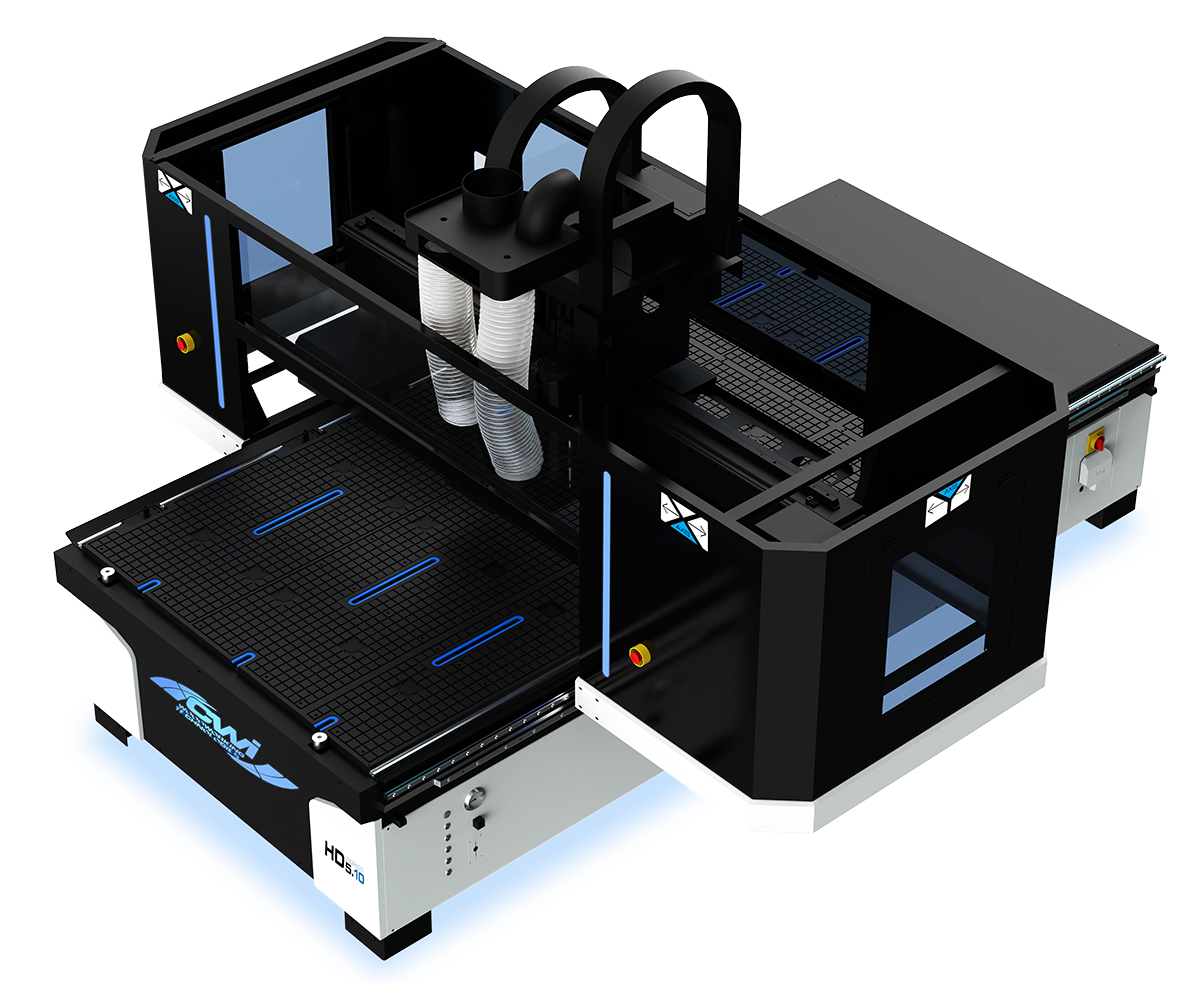

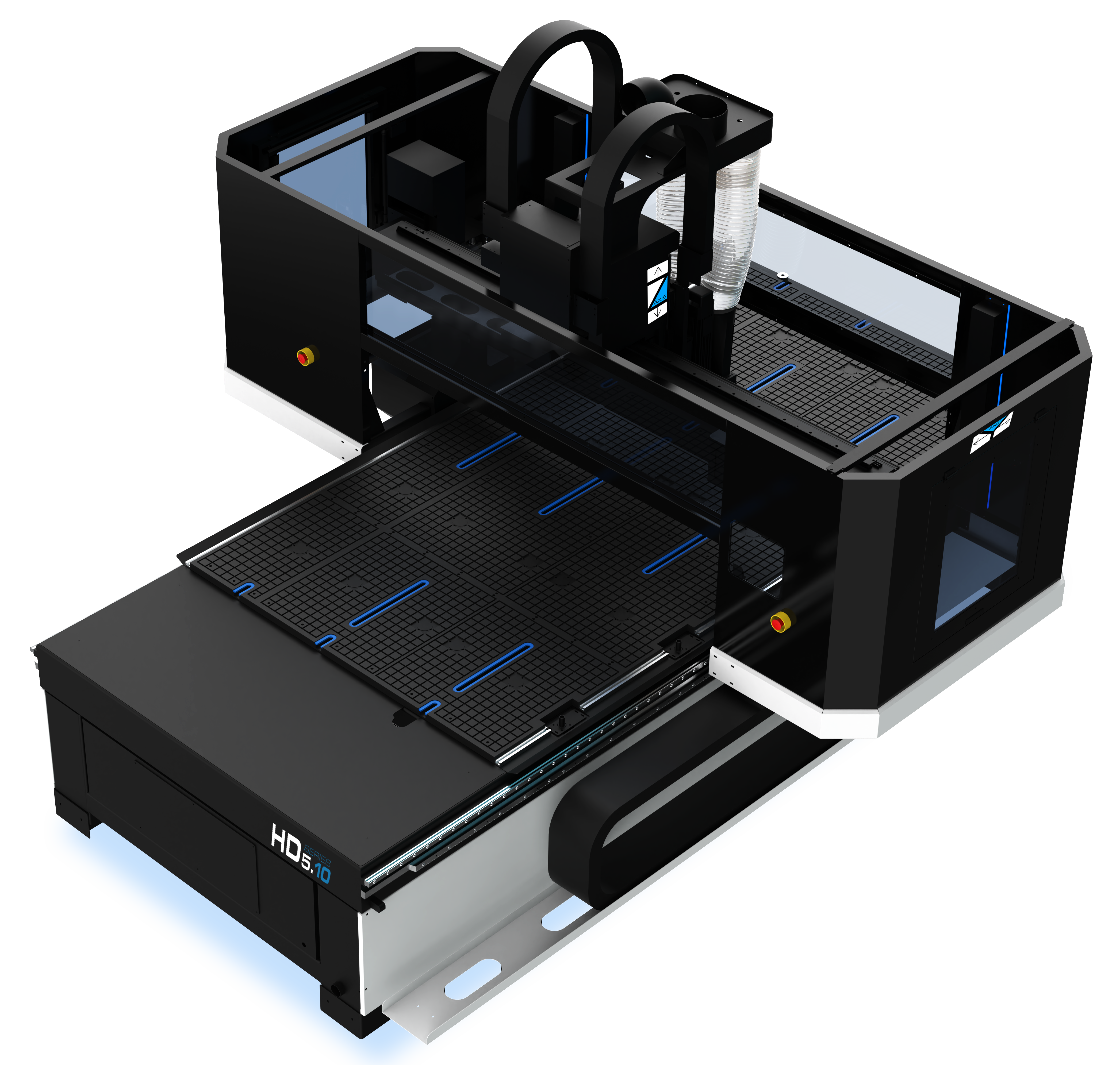

The CabinetMaker HD has the quality, features, performance, and value to get the job done. The biggest improvement of the CabinetMaker HD over our standard CabinetMaker CNC is the addition of a much heavier frame, rotary tool changer on the gantry, larger router spindle power, a 9 spindle drilling head and a fully enclosed safety hood around the working areas of the machine.

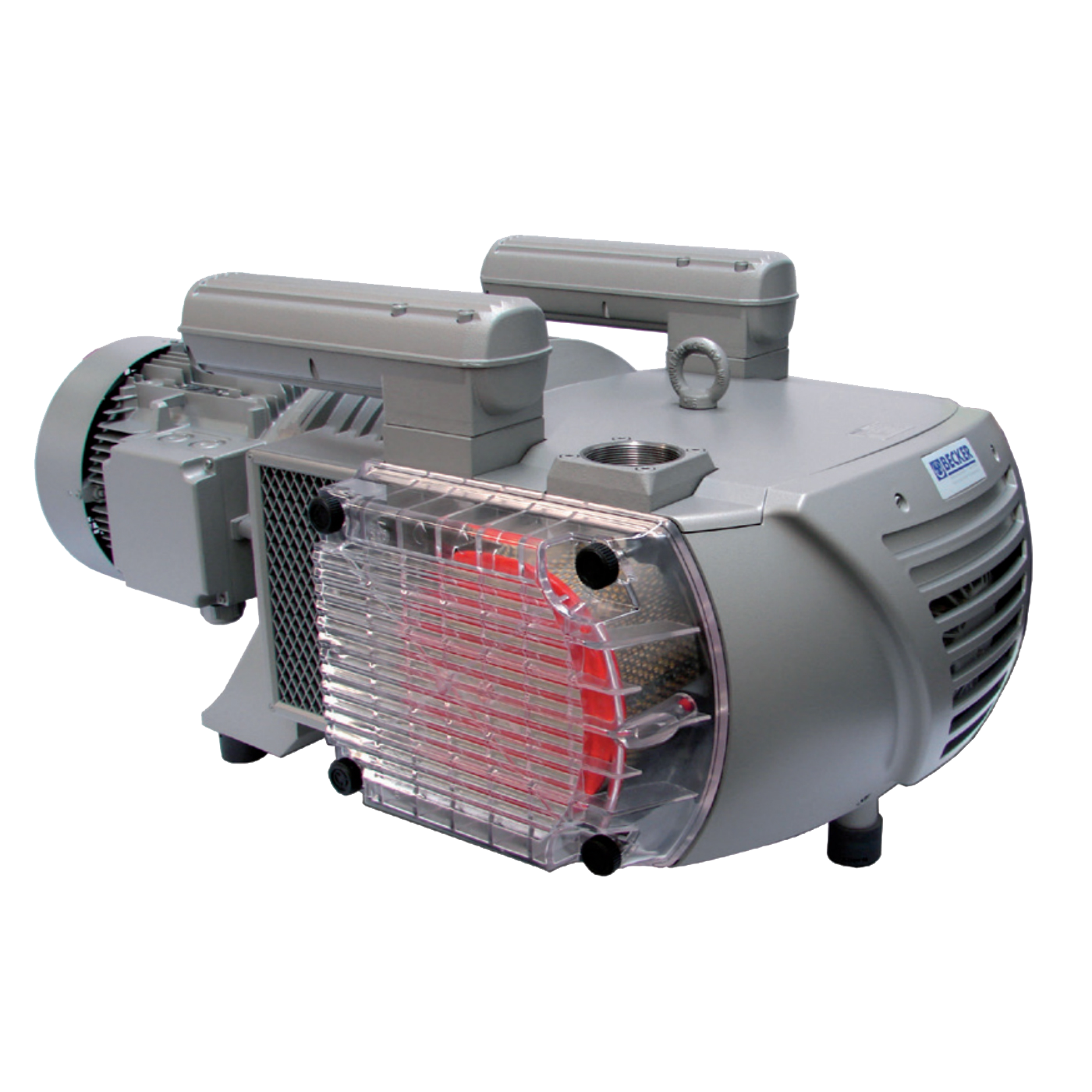

Like all CNC built by CWI, the CabinetMaker HD offers better performance, quality, components and features than any competitive machine in its class. The base of the machine is a 6000 pound very heavy duty welded steel floor model frame. The Bakelite vacuum table is mounted to the steel frame for an excellent working vacuum surface. The German made Becker 300 cubic meter per hour vacuum pump offers plenty of holding power to keep parts in place while machining. Under the frame are six heavy duty 6” diameter adjustable feet to make sure of a solid footing on the shop floor.

Like all CNC built by CWI, the CabinetMaker HD offers better performance, quality, components and features than any competitive machine in its class. The base of the machine is a 6000 pound very heavy duty welded steel floor model frame. The Bakelite vacuum table is mounted to the steel frame for an excellent working vacuum surface. The German made Becker 300 cubic meter per hour vacuum pump offers plenty of holding power to keep parts in place while machining. Under the frame are six heavy duty 6” diameter adjustable feet to make sure of a solid footing on the shop floor.

The massive gantry rides on extremely accurate Japanese linear guide ways driven by helical rack and pinion for each of “X”, “Y” and “Z” movements. The gantry movement is powered by Yaskawa servo motors and controllers for a cutting speed of up to 1100 inches per minute and a travelling speed up to 3500 inches per minute. We use two 1.3 KW servo’s for the “Y” axis, one 1.3 KW for X and one 750 watt for “Z”. Having two servo’s on the “Y” (length of the machining area) is very important for performance, strength and accuracy of the machining process.

The Cabinetmaker HD also uses Yaskawa servo’s to drive the 9 spindle drill head as well as the 12 position rotary tool changer.

The Cabinetmaker HD also uses Yaskawa servo’s to drive the 9 spindle drill head as well as the 12 position rotary tool changer.

The gantry and working areas of the machine are surrounded by a safety cabinet with emergency stops on all four sides of the machine. Each of the spindles use automatic dust hoods with 6″ hoses to a main 8″ dust collection inlet above the machine. There are pneumatically controlled connections to the drill head, router spindle and pusher bar for cleaning the table surface.

The router spindle is a high quality continuous duty cycle, Italian made HSD 9.6kw (13 HP) HSK-63 three phase motor which comes with 1/4”, 3/8”, 1/2”and 20mm high precision ER32 collets. HSD is one of the leading manufacturers of CNC spindles throughout the world and are used on all CWI high production CNC’s.

The Italian made HSD 1.7 KW 9 spindle drilling head offers 32mm increments in an “L” shape allowing up to 5 shelf holes to be drilled at a time. The advantage of the drilling head alongside the router spindle is it allows the machine to drill shelf holes, 8mm and 35mm holes without the machine having to take the time to change tool holders.

The Italian made HSD 1.7 KW 9 spindle drilling head offers 32mm increments in an “L” shape allowing up to 5 shelf holes to be drilled at a time. The advantage of the drilling head alongside the router spindle is it allows the machine to drill shelf holes, 8mm and 35mm holes without the machine having to take the time to change tool holders.

Also improving machining speed is the rotary tool holder attached to the gantry with 12 holder positions ( 16 and 20 Positions Optional) for the HSK-63 chucks and tooling. Having the tool changer on the gantry saves time in the machining process so the spindle only travels to the end of the gantry to load tools instead of traveling to the back of the machine.

At the back of the machine is a tool changing station and wrench for quick and easy changes of tooling. There are two tool measuring devices on the machine, one at the back of the machine for automatic measures and a second moveable one for measuring tools “on the go”.

An automatic centralized lubrication system is standard making maintenance on the Japanese THK linear guideways a simple process.

At the back of the machine is a tool changing station and wrench for quick and easy changes of tooling. There are two tool measuring devices on the machine, one at the back of the machine for automatic measures and a second moveable one for measuring tools “on the go”.

An automatic centralized lubrication system is standard making maintenance on the Japanese THK linear guideways a simple process.

The machining area of the HD5.10 is oversized for convenience at 61 3/4″ x 121 1/2″ with a clearance height of 12″. For ease of machining we include a set of six pneumatic reference pins which allows the operator to quickly and accurately locate the work piece in the same home position every time. No mistaking where your router bit will find the work piece.

The electrical components and controls of the CabinetMaker HD are conveniently enclosed in the base of the machine with easy access doors. Here you will find Siemens CSA contactors, fuses and holders, Delta Inverter, Omron safety switch controls, and Yaskawa Digital Servo controls. We use Omron micro limit switches for controlling stops and movements of the home positioning. The CabinetMaker HD is fully CSA certified for use in Canadian commercial applications or anywhere users need higher quality electrical protection.

The Syntec 21MA-E controller and keyboard are mounted to a separate mobile operations stand for ease of control of the operations of the machine. Also included is a magnetic hand held manual controller. The manual controller lets the operator make trial runs of a program with a hand operated dial. This allows testing of a program or cutting height without danger or to make quick to adjustments in the program for accidental tooling issues.

Also included with the CabinetMaker HD is the German made Becker 300 cubic meter per hour vacuum pump which offers plenty of holding power to keep parts in place while machining.

The six vacuum zones are operated by 6 electrical push button actuated valves for simple operation.

The six vacuum zones are operated by 6 electrical push button actuated valves for simple operation.

The CabinetMaker HD will offer better performance, world class components, quality, and features than any competitive machine in its class.

Specifications:

– Working size: 61 3/4” x 121 1/2” x 12” (5’ x 10’) (Optional 4’ x8’ Available)

– 13 HP (9.6 KW)(S1) HSD HSK-63 Italian ATC Industrial Air Cooled Spindle

– Servo Controlled 9 Spindle HSD 1.7 KW Italian made Drilling head

– Pneumatically Controlled Vacuum Connections (8” Port)

– Servo Controlled 12 Positions Rotary Tool Holder Magazine (16 or 20 Optional)

– Automatic Tool Measuring System w/Pneumatic Clean Devise

– Additional Moveable Manual Tool Measure

– Automatic Lubrication System

– HSK-63 Tool Holders (One Included w/machine)

– ER32 Collets (1/4”, ½” 3/8” and 20mm Included with machine)

– Tool Holder Wrench

– Convenient Tool Changing Station

– Bakelite Vacuum Table w/Six Zone Control

– Electronic Valves 6 Push Button Zone Activation

– Becker 300 cm/h German Made Vacuum Pump

– Syntec 21MA-E Control System

– Under Table Electronics Cabinet w/Easy access Door

– USB Information Transfer Ports

– Magnetic Manual Machine Movement Controller

– Yaskawa Digital 1.3 KW x 3 and 750 Watt x 3 Servo Drivers and Motors

– Six Pneumatic Reference Pins (for aligning work piece)

– Japanese Omron Limit Micro Switches

– DELTA Three Phase Motor Inverter

– SHIMPO Servo Gear Reducers

– German Helical Rack & Pinion

– Robust Cable Holding Carrier Rated for over 300,000 bends

– Traveling Speed 90M/min (3540”/min)

– Siemens CSA Contactors and Breakers

– Japanese Omron Limit Micro Switches

– CSA Certification

– THK Linear Rails

– 3PH 220V 60HZ (80 amp Breaker Required)

– Shipping Weight 6000 lbs

– Working size: 61 3/4” x 121 1/2” x 12” (5’ x 10’) (Optional 4’ x8’ Available)

– 13 HP (9.6 KW)(S1) HSD HSK-63 Italian ATC Industrial Air Cooled Spindle

– Servo Controlled 9 Spindle HSD 1.7 KW Italian made Drilling head

– Pneumatically Controlled Vacuum Connections (8” Port)

– Servo Controlled 12 Positions Rotary Tool Holder Magazine (16 or 20 Optional)

– Automatic Tool Measuring System w/Pneumatic Clean Devise

– Additional Moveable Manual Tool Measure

– Automatic Lubrication System

– HSK-63 Tool Holders (One Included w/machine)

– ER32 Collets (1/4”, ½” 3/8” and 20mm Included with machine)

– Tool Holder Wrench

– Convenient Tool Changing Station

– Bakelite Vacuum Table w/Six Zone Control

– Electronic Valves 6 Push Button Zone Activation

– Becker 300 cm/h German Made Vacuum Pump

– Syntec 21MA-E Control System

– Under Table Electronics Cabinet w/Easy access Door

– USB Information Transfer Ports

– Magnetic Manual Machine Movement Controller

– Yaskawa Digital 1.3 KW x 3 and 750 Watt x 3 Servo Drivers and Motors

– Six Pneumatic Reference Pins (for aligning work piece)

– Japanese Omron Limit Micro Switches

– DELTA Three Phase Motor Inverter

– SHIMPO Servo Gear Reducers

– German Helical Rack & Pinion

– Robust Cable Holding Carrier Rated for over 300,000 bends

– Traveling Speed 90M/min (3540”/min)

– Siemens CSA Contactors and Breakers

– Japanese Omron Limit Micro Switches

– CSA Certification

– THK Linear Rails

– 3PH 220V 60HZ (80 amp Breaker Required)

– Shipping Weight 6000 lbs

Options Available:

– Working Area 4’ x 8’

– 16 or 20 Position Tool Changer

– Additional Vacuum Pump

– 18 Spindle Drill Head

– 13.2 KW Router Spindle

– Software

– Tooling

– Delivery and installation

– Training

– Working Area 4’ x 8’

– 16 or 20 Position Tool Changer

– Additional Vacuum Pump

– 18 Spindle Drill Head

– 13.2 KW Router Spindle

– Software

– Tooling

– Delivery and installation

– Training

Confirm Availability & Shipping for the CabinetMaker CWI-CNC60120C-HD